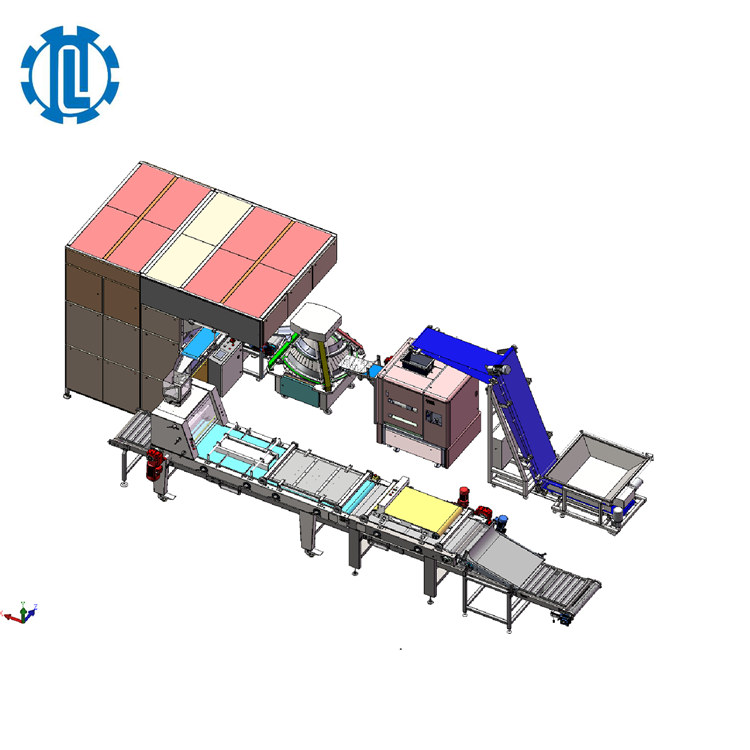

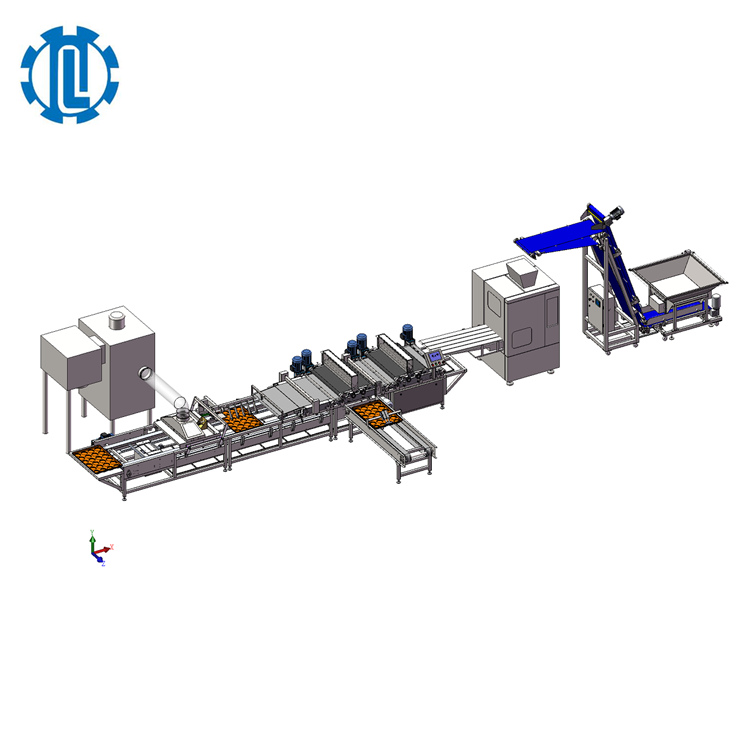

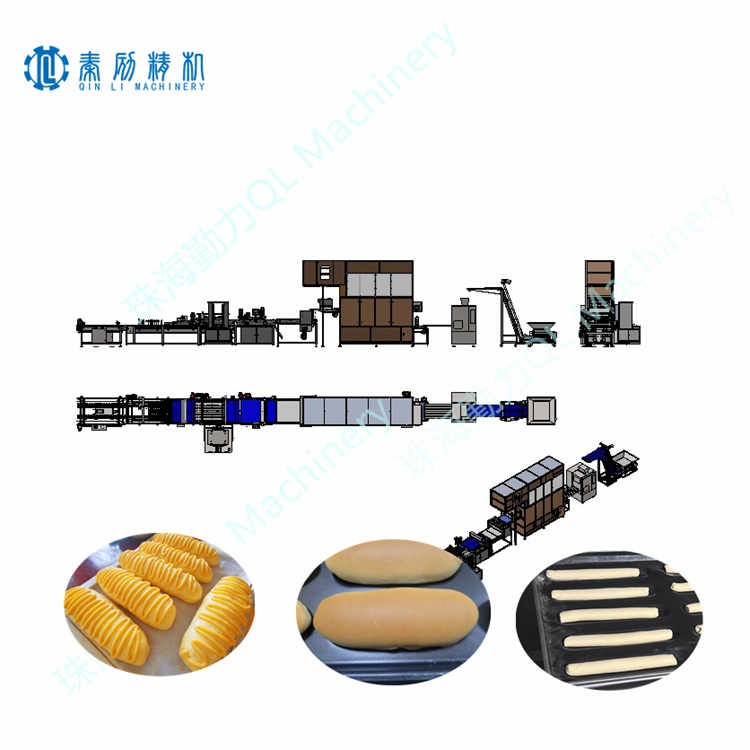

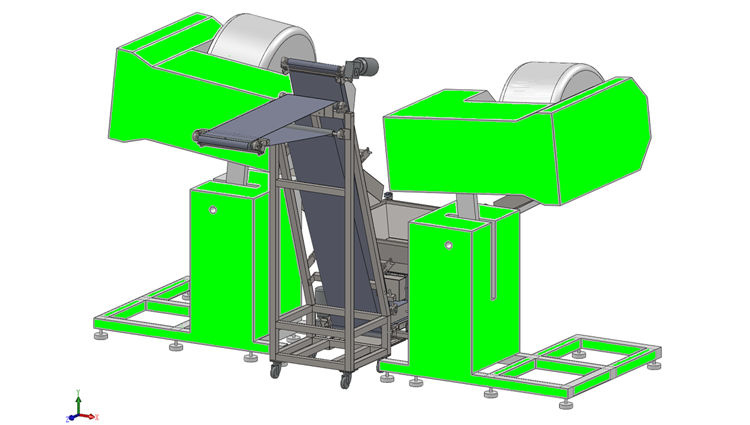

Long Loaf Bread Forming Line QLLM-T3

Fully automatic long loaf bread forming line, capacity 2,000-4,000 pcs/h, dough ball resting time 8-12 minutes.

Feature:

Volumetric dividing method, helps to get smaller error and good dough inner structure.

Dough balls weight, resting time, molding process are all adjustable.

Whole line work in LINKED model, also viable in independent model;

Increase production efficiency, save labor, and reduce production costs.

Application:

Automatic forming for Toast bread, long loaf bread,sandwich bread,artisan bread,white bread,loaf pan forming.

Product Description

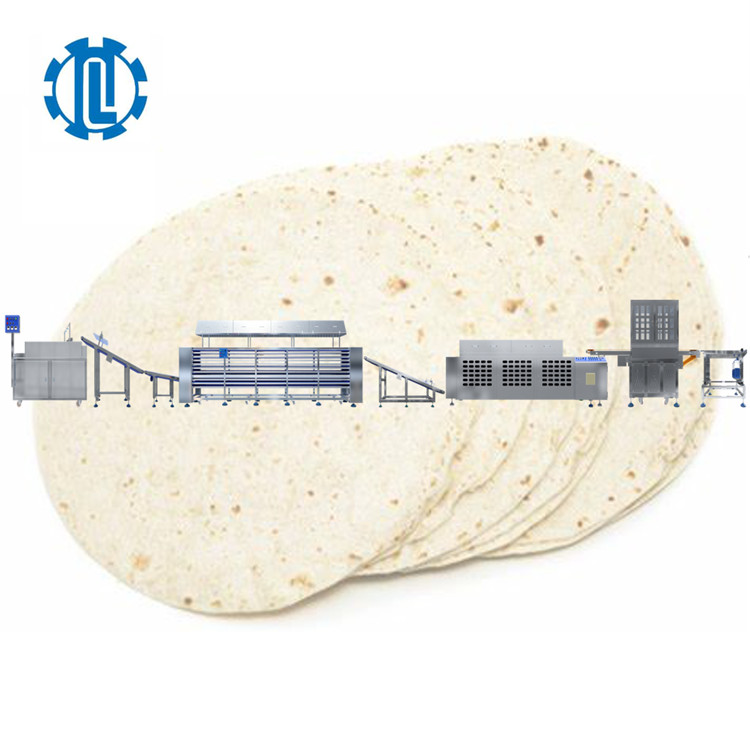

Loaf Bread Forming Line is state-of-the-art bakery equipment designed to automate the process of bread loaf formation. This advanced machinery is engineered to produce consistent and uniform bread loaves with minimal manual intervention, ensuring high efficiency and productivity in commercial bakeries.

Enhance your loaf bread production with our efficient Loaf Bread Forming Line. Designed to mold and shape bread loaves with precision, our Long bread production line ensures consistent quality and maximizes output. Ideal for bakeries looking to streamline their process, our advanced Loaf Bread molder delivers high-quality results, reducing labor costs and boosting productivity. Trust us for your loaf bread-forming needs.

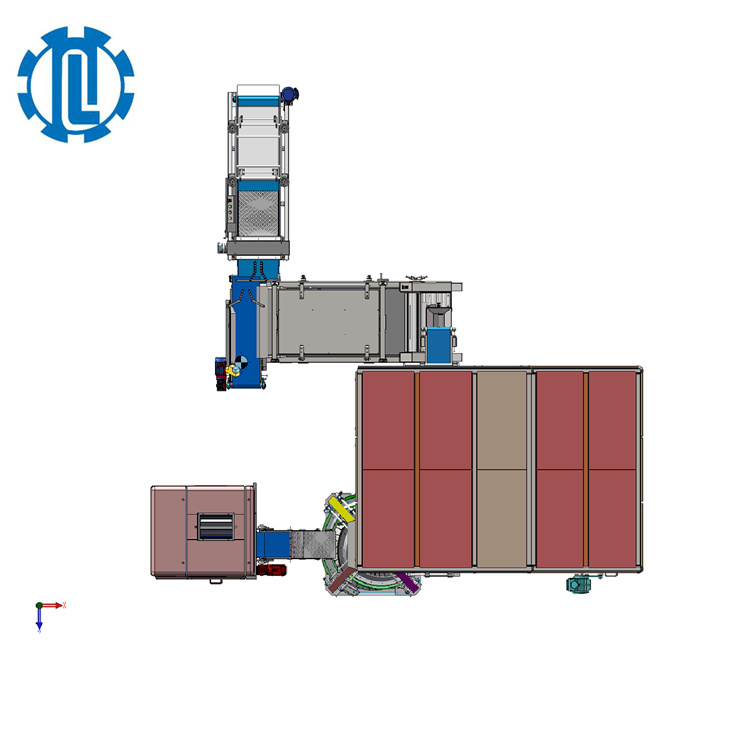

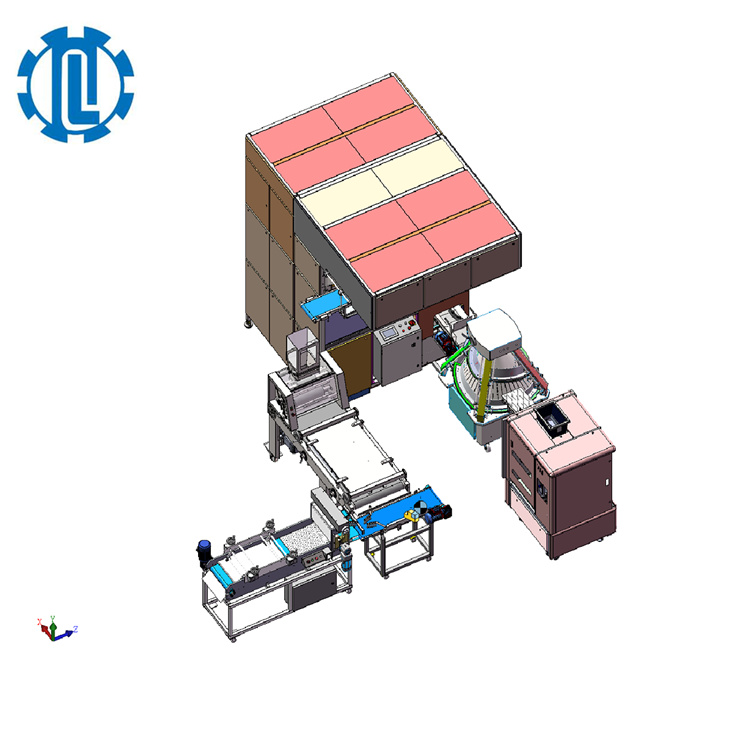

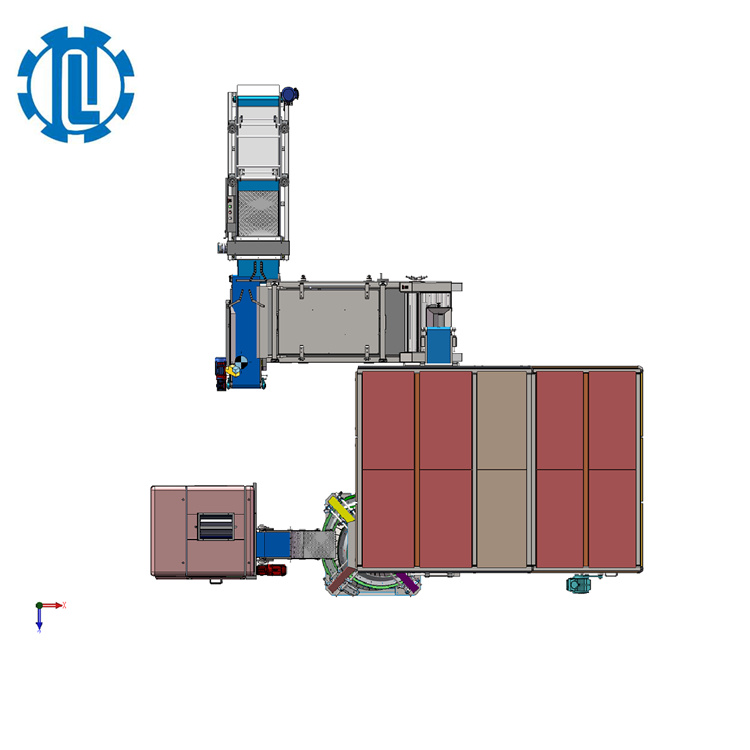

Long Loaf Forming Line Technical Parameters:

| Model | Dough weight range | Max capacity | Dimension (mm) |

| QLLM-T3 | 50-1000g | 3000pcs/h | 8500*5000*2600 |

Note: Accept non-standard customization

The Loaf Bread Forming Line is an essential piece of equipment for any commercial bakery looking to streamline their production process, increase efficiency, and produce high-quality bread loaves consistently. Get your free quote now.

Long Loaf Forming Line Details:

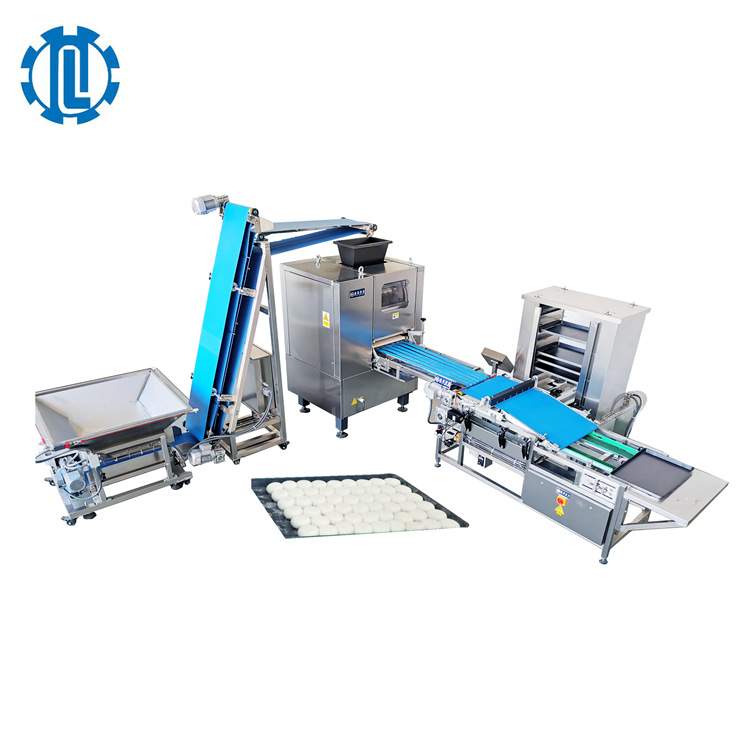

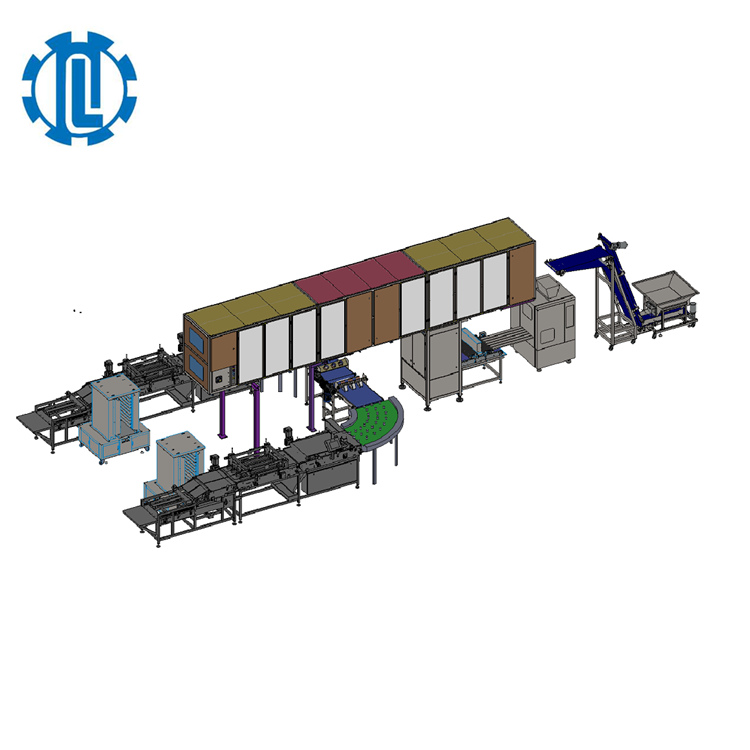

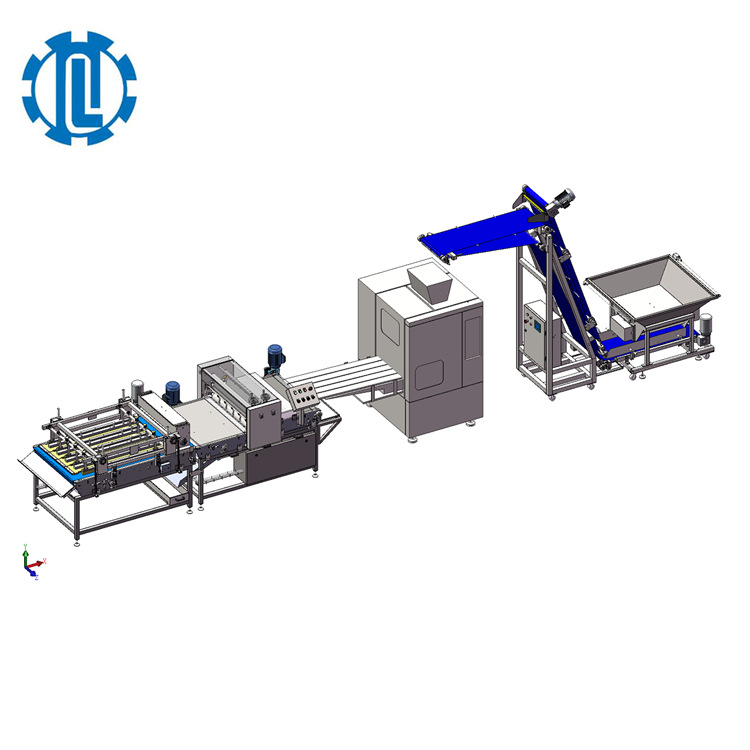

The Loaf Bread Forming Line features a fully automated system that includes dough feeding, weighing, rounding, molding, and panning. The machine is equipped with a high-precision weight control system that ensures accurate portioning of the dough, resulting in consistent loaf sizes and weights.

The rounding and molding units are designed to shape the dough into perfect loaf forms, eliminating any human error or inconsistencies in the final product. The panning unit then automatically transfers the molded dough into baking pans, ready for proofing and baking.

The Loaf Bread Forming Line is constructed using high-quality materials and components, ensuring durability and longevity in even the most demanding production environments. The machine's compact design also makes it easy to integrate into existing bakery operations without requiring significant space or infrastructure modifications.

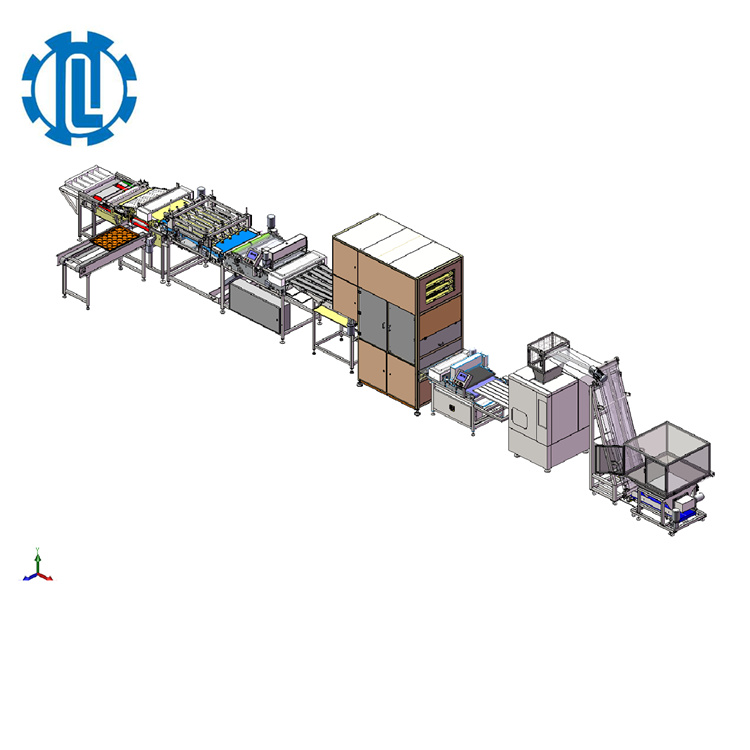

The Loaf Bread Forming Line is listed as follows:

1. Dough mixer

2. Dough divider elevator

3. Dough divider

4. Conical rounder

5. Intermediate proofer

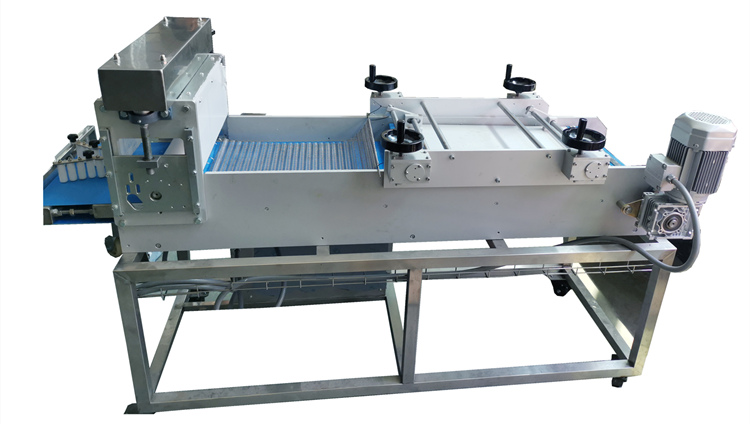

6. loaf bread first moulder

7. loaf bread second moulder

Key Features of Loaf Bread Forming Line:

Automated Dough Handling:

● Precision Mixing: The line starts with high-capacity mixers that ensure a uniform blend of ingredients, resulting in consistently high-quality dough.

● Automated Transfer: Dough is automatically transferred from the mixer to the next stage, minimizing manual handling and contamination risks.

Dough Dividing and Rounding:

● Accurate Portioning: Advanced dough dividers precisely portion the dough, ensuring each loaf is of uniform weight and size.

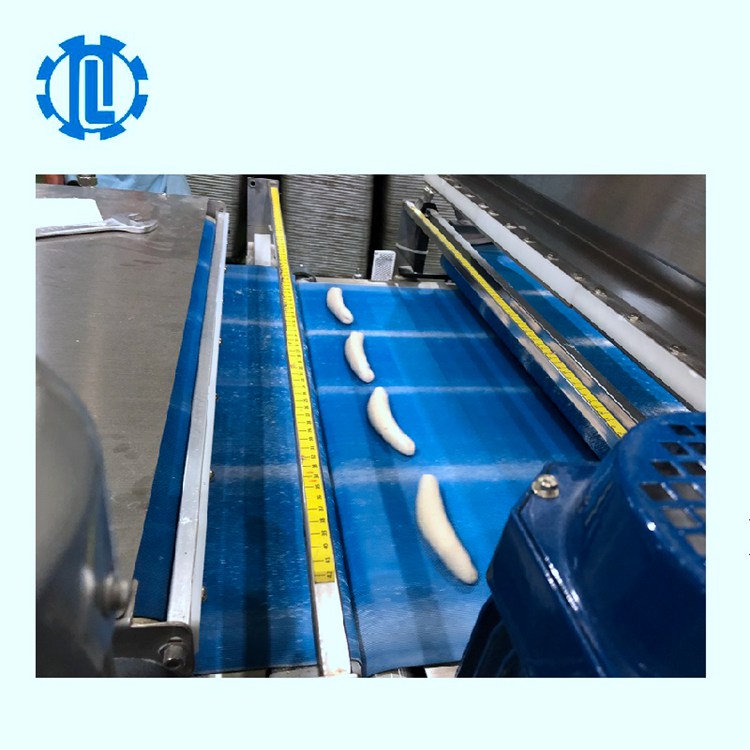

● Efficient Rounding: The rounded dough balls are then shaped to ensure even texture and structure, ready for further processing.

Intermediate Proofing:

● Controlled Environment: The intermediate proofer provides a controlled environment for the dough to rest and ferment, ensuring optimal rise and texture.

● Adjustable Settings: Temperature and humidity settings can be adjusted to meet specific recipe requirements.

Loaf Molding:

● Consistent Shaping: The dough is carefully molded into loaf shapes, maintaining uniformity and ensuring a high-quality final product.

● Versatile Configurations: The molding equipment can be adjusted for various loaf sizes and shapes, providing flexibility for different product lines.

Final Proofing:

● Precision Control: Final proofers offer precise control over the proofing conditions, ensuring the dough rises perfectly before baking.

● Even Proofing: Uniform proofing conditions guarantee that every loaf achieves the desired volume and texture.

Optional Features:

● Seed and Topping Applicators: Option to add seeds, grains, or other toppings for product variety.

● Customization: Modular design allows for customization to meet specific production needs. Technical Support.

Loaf Bread Forming Line Benefits:

● The automated process reduces manual labor and speeds up production, allowing for higher output with consistent quality.

● Precision equipment ensures that every loaf is made to exact specifications, resulting in uniformity across batches.

● The automated system minimizes human contact with the dough, reducing the risk of contamination and ensuring a hygienic production process.

● The Loaf Bread Moulder can be customized to produce a wide range of loaf sizes and types, catering to diverse market demands.

Loaf Bread Forming Line Applications:

● Industrial Bakeries: Ideal for large-scale bakery operations that require high throughput and consistent quality.

● Artisanal Bakeries: Provides artisanal bakers with the capability to scale up production while maintaining product integrity.

● Food Service: Suitable for food service companies needing reliable and efficient bread production solutions.

The Loaf Bread Forming Line is an essential investment for bakeries seeking to enhance their production efficiency, product consistency, and overall quality. With its advanced features and customizable options, this forming line is the ideal solution for meeting the demands of a competitive bakery market. Contact us today to learn more about how this innovative system can transform your bakery operations.