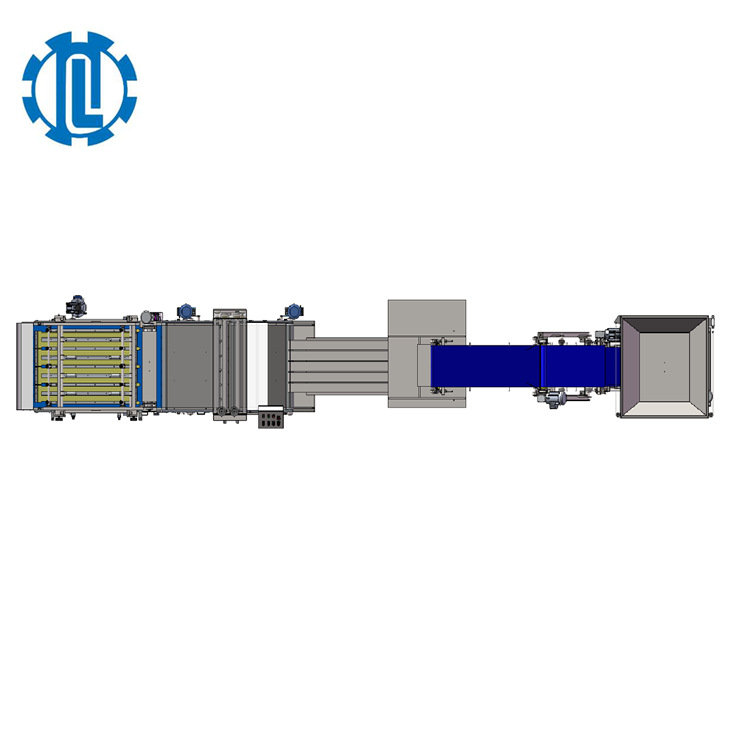

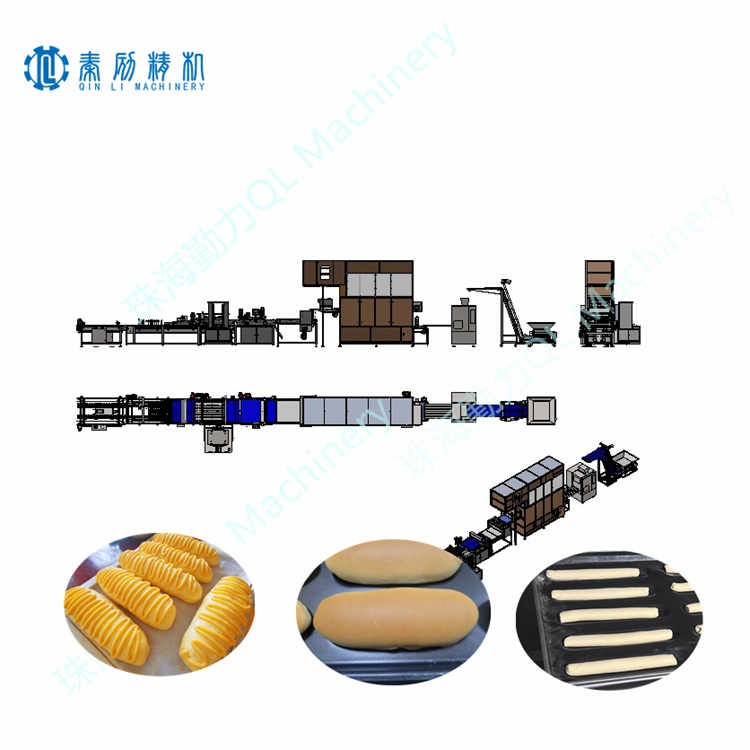

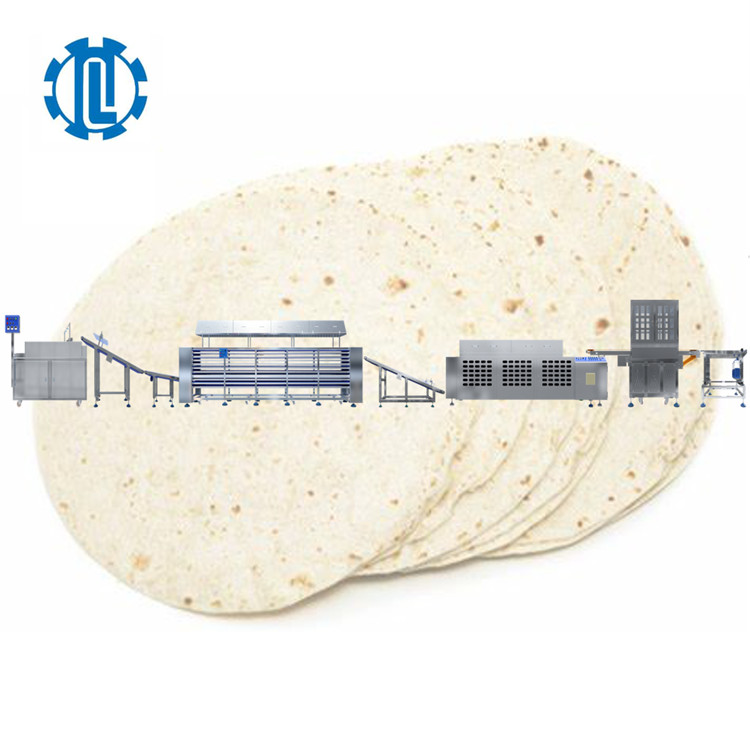

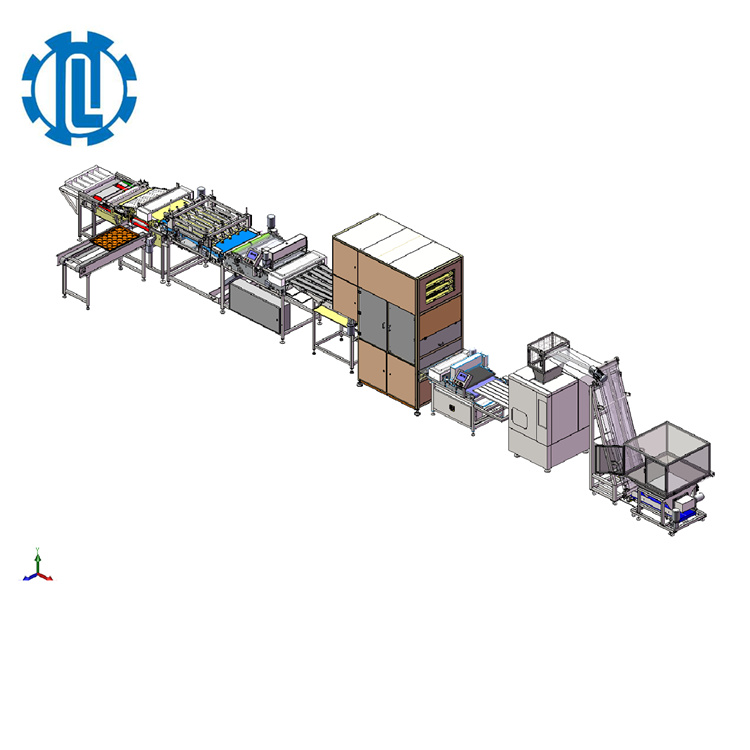

Semi-Automatic Hot Dog Buns Forming Line QLLE-C6

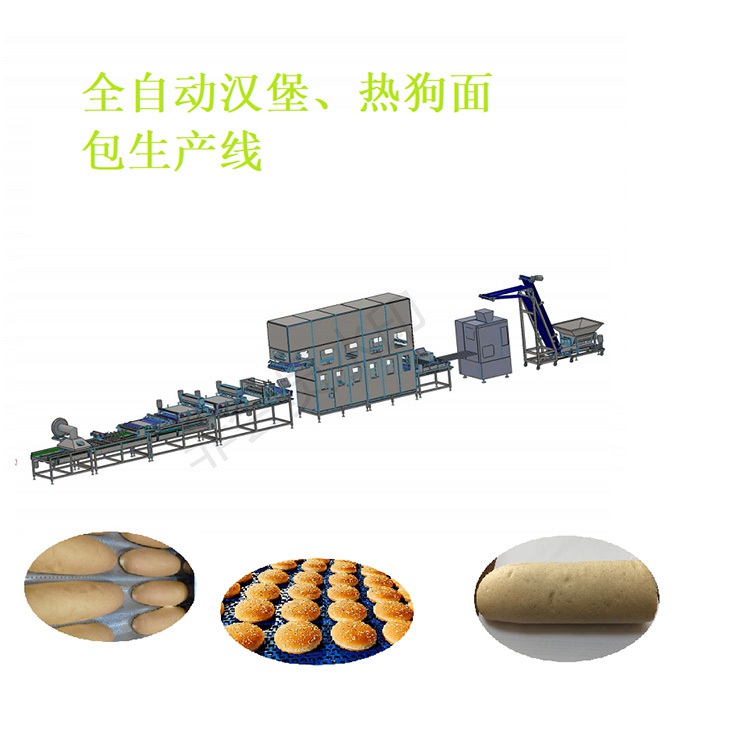

Semi-automatic hot dog buns forming line, can shape 6", 8", 10", 12" hot dog bread and burger buns.

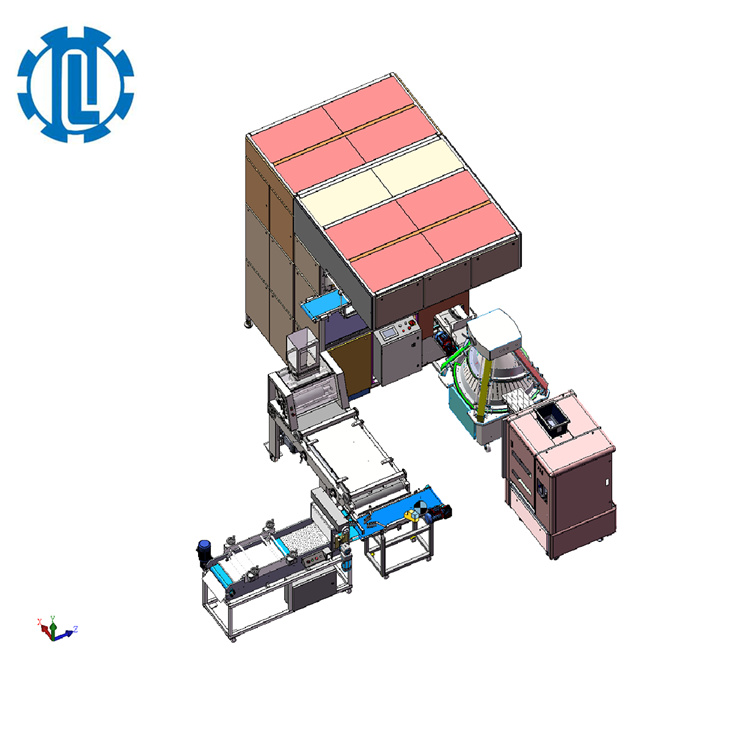

★Burger buns shaping process:

dough mixing-dough dividing& rounding& slight flatting-Double roller press-Flour dusting-manual pick dough buns up.

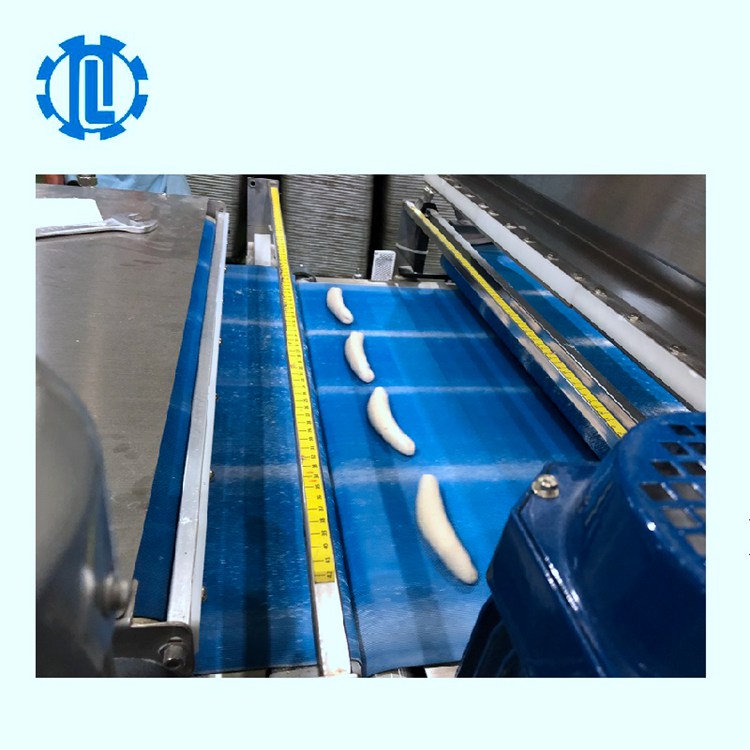

★Hot dog buns shaping process:

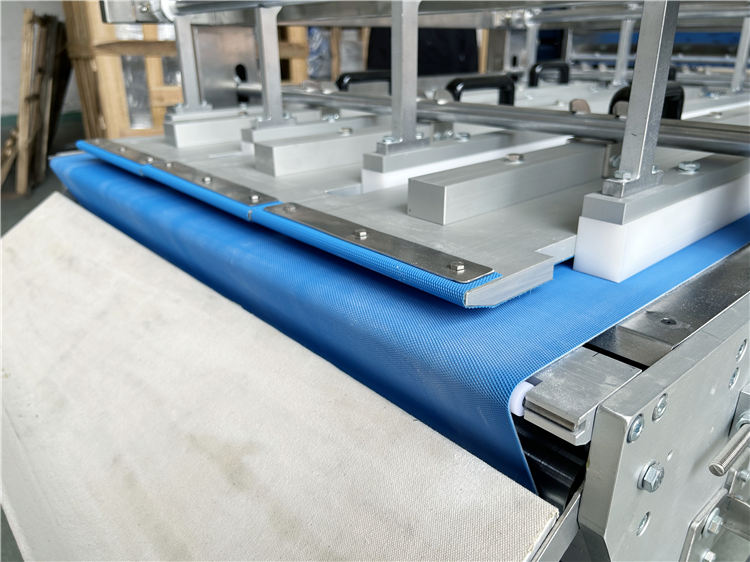

dough mixing-dough dividing& rounding& slight flatting-Double roller press & curl chain rolling-Flour dusting-pressure plate rolling-manual pick buns up.

Product Description

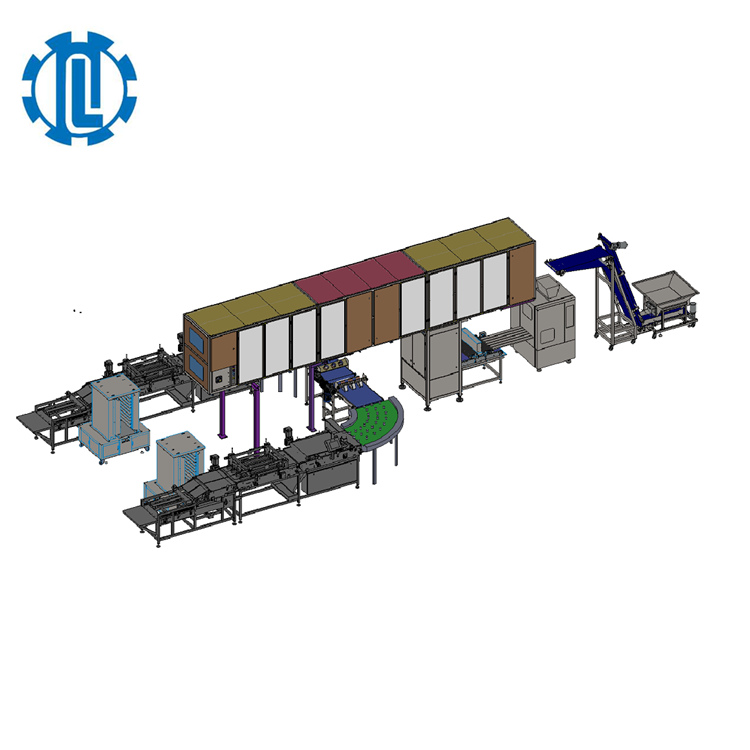

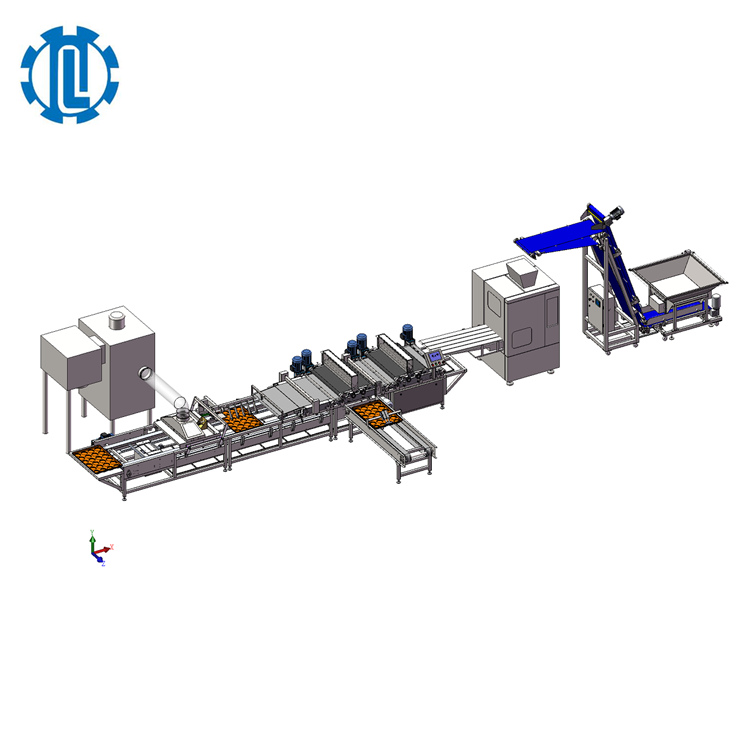

A Semi-Automatic Hot Dog Buns Forming Line is an industrial system designed to streamline the production of hot dog buns with a combination of manual and automated processes. This is a machine that can form hot dog buns automatically. It can mix flour and other ingredients, knead the dough, shape it into buns, and bake them. The process is fully automated, which improves efficiency and reduces labor costs.

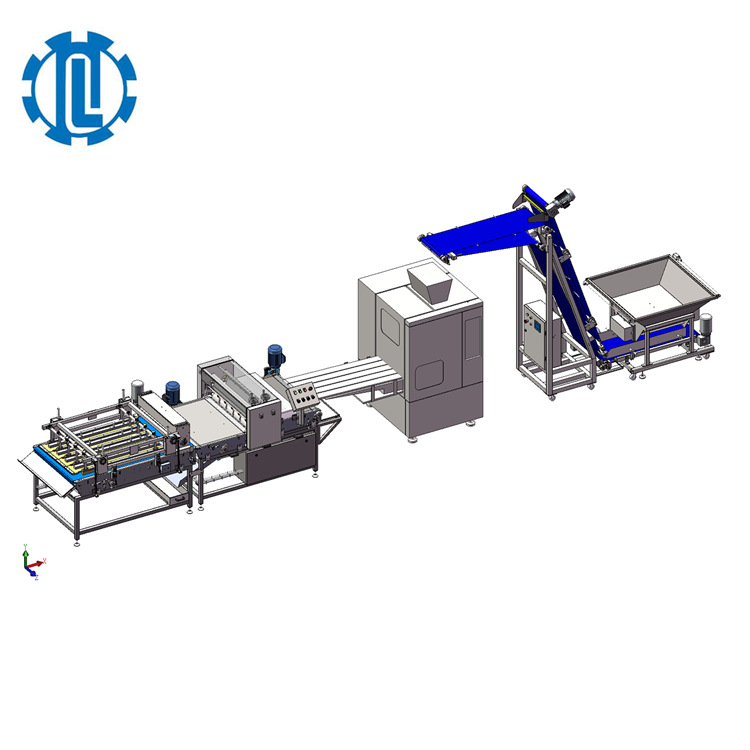

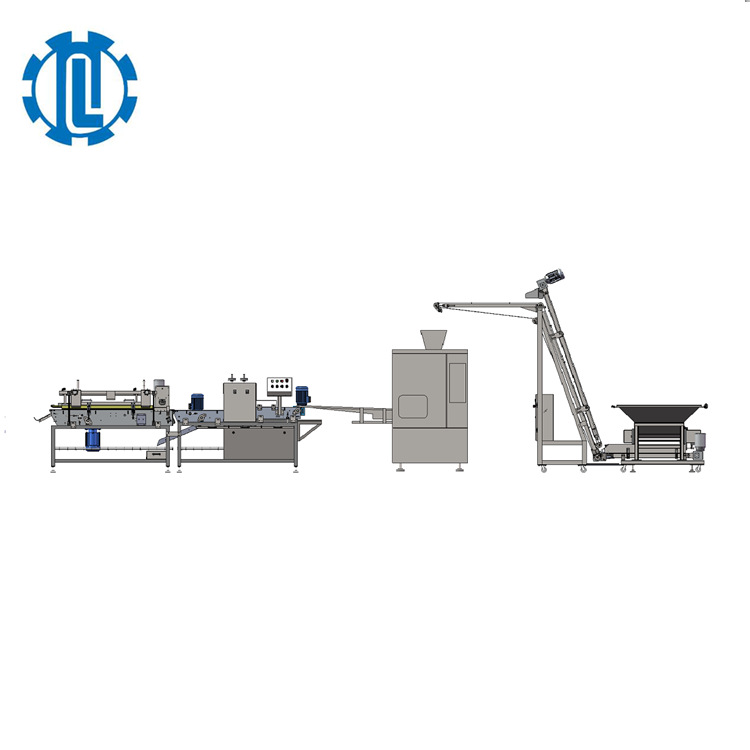

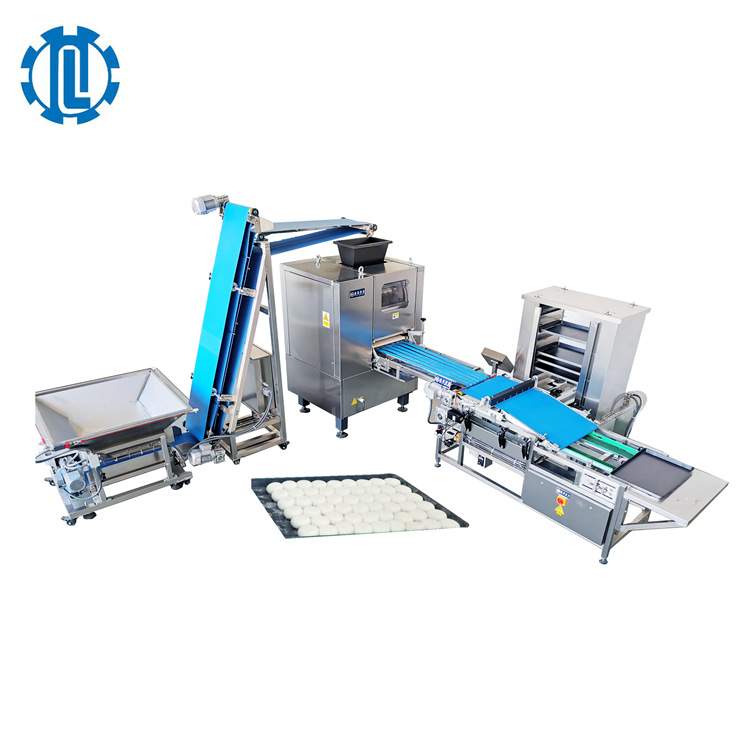

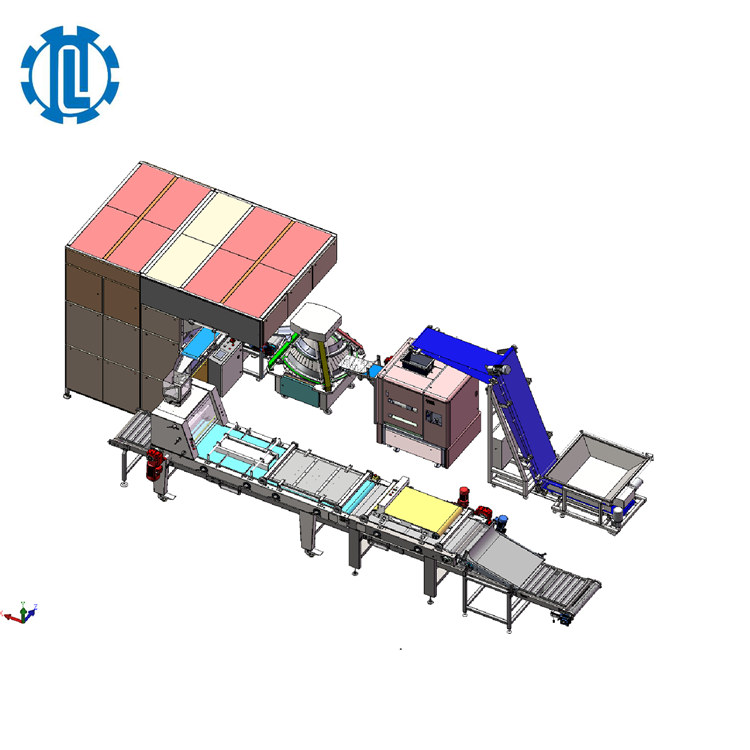

The semi-automatic hot dog buns forming line consists of several parts: the mixing machine, the kneading machine, the shaping machine, and the baking oven. The mixing machine combines the ingredients and ensures they are evenly distributed. The kneading machine then kneads the dough to the right consistency. The shaping machine forms the dough into buns, and the baking oven bakes the buns to perfection. The machine can be programmed to make buns of different sizes and shapes, depending on the requirements. It can also adjust the baking time and temperature according to the recipe.

The semi-automatic hot dog buns forming line is an efficient and cost-effective solution for businesses that need to produce large quantities of hot dog buns quickly and consistently. It integrates manual expertise with automated precision, resulting in an efficient and consistent production process suitable for medium-sized bakeries or food production facilities.

Semi-Automatic Hot Dog Buns Forming Line Specification

| Model | Bread | Weight range | Max capacity | Dimension (mm) |

| Single lineQLLE-C6 | 6-inch hotdogs | 28-130g | 6,000 pcs/h | 9000*1440*2800 |

| 8-inch hotdogs | 28-130g | 4,500 pcs/h | ||

| 10-inch hotdogs | 28-110g | 4,500 pcs/h | ||

| 12-inch hotdogs | 28-130g | 3,000 pcs/h | ||

| 4-inch burger | 28-130g | 12,000 pcs/h |

In addition to a semi-automatic hot dog bun forming line, we also provide a fully automatic hot dog bun forming line. You can contact us at any time to adjust your plan.

Semi-Automatic Hot Dog Buns Forming Line Features:

▲It's possible to produce both hot dog and burger buns by model switch.

▲The forming process can be customized according to demands.

▲Saving of raw materials due to the high weight accuracy of the dough balls.

▲Each machine is equipped with an induction device to ensure the continuity of the production line.

▲Application: Compatible with the molding of burgers and hot dogs.

Semi-Automatic Hot Dog Buns Forming Line Equipment list:

▲Dough divider elevator, for automatic dough feeding.

▲Dough divider rounder, for dough balls dividing rounding.

▲Moulder machine, for hot dog buns and burger buns moulding.

★Accept non-standard customization, Contact us for a commercial-use machine for hamburgers & hotdogs.

Semi-Automatic Hot Dog Buns Forming Line Advantages:

◆ High Accuracy of Dough Ball Weight

◆ Easy for Cleaning

◆ Special Designed for Hamburger Bun, Hot Dog, etc.

◆ Industrial Hamburger/Hot Dog Bun Systems

◆ Increases production speed compared to manual processes.

◆ Ensures uniform size and shape of buns.

◆ Allows manual adjustments, providing flexibility to handle variations in dough or recipe.

◆ Lower initial investment and maintenance costs compared to fully automated systems.

◆ Operators can perform quality checks at various stages.

Considerations for Implementation

◆ Space Requirements: Adequate space for machinery and manual operations.

◆ Skill Level: Training for operators to manage semi-automated processes effectively.

◆ Maintenance: Regular maintenance schedules to ensure machinery operates smoothly.

◆ Scalability: Ability to upgrade or expand the line as demand increases.

◆ Sanitation: Ensuring all components are easy to clean and meet food safety standards.

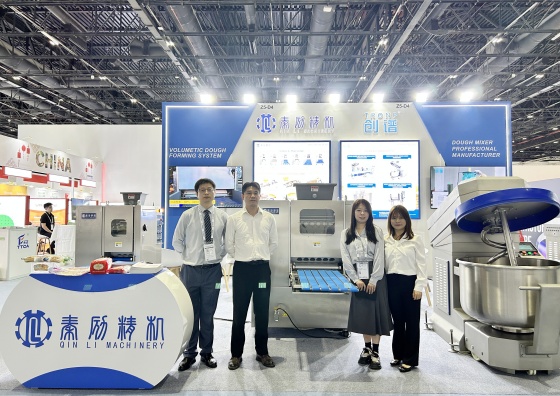

About Us

Qinli Machinery is located in Zhuhai City, Guangdong Province, which is a beautiful and economically developed coastal city. As a professional company specializing in manufacturing baking machines and supplying services, we have great advantages of technology background. Our team is professional in design, manufacture, and sales. Products contain a variety of precision baking Machines, such as Hamburger/Tortilla/Hotdog /pita production line, Dough divider rounder, Moulder, Dough conveyor, Intermediate proofer, Dough extruder, Pita Moulder, seeds sprinkler, and so on.

1. A complete set of our own team to support your selling. We have an outstanding R&D team, a strict QC team, an exquisite technology team and a good service sales team to offer our customers the best service and products. We are both manufacturer and trading company.

2. We have our own factories and have formed a professional production system from material supply and manufacture to sale, as well as a professional R&D and QC team. We always keep ourselves updated with market trends. We are ready to introduce new technology and services to meet the market needs.

3. Quality assurance. We have our own brand and attach much significance to quality. The manufacture of food machines maintains BG/T19001-2016/ISO9001:2015 and CE Quality Management Standard.

Why Choose Qinli?

1. About price: The price is negotiable. It can be changed according to your quantity or package.

2. About goods: All our goods are made of high-quality food-grade materials.

3. About MOQ: We can adjust it according to your requirements.

4. About exchange: Please email me or chat with me at your convenience.

5. High quality: Using high-quality material and establishing a strict quality control system, assigning specific persons in charge of each process of production, from raw material purchase to pack.

FAQ

1. Are you a factory or trading company?

We are a factory and with Export Right. It means factory + trading.

2. How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

3. What can you buy from us?

Baking Equipment and production line accessories.

4. why should you buy from us not from other suppliers?

Our core technology team has more than 15 years of experience in the baking industry, focusing on dough process equipment, such as dough divider rounders and burger/ hotdog molders and so on

5. what services can we provide?

Accepted Delivery Terms: FOB, CIF;

Accepted Payment Currency: USD, EUR, HKD, CNY;

Accepted Payment Type: T/T, MoneyGram, Credit Card, PayPal, Western Union;

Language Spoken: English, Chinese

6.. How do I believe you?

We consider honesty as the life of our company, besides, high-quality equipment manufacturers and respected service providers. Every customer would be a treasure to Qinli. Your satisfaction is our driving force., your order and money will be well guaranteed.