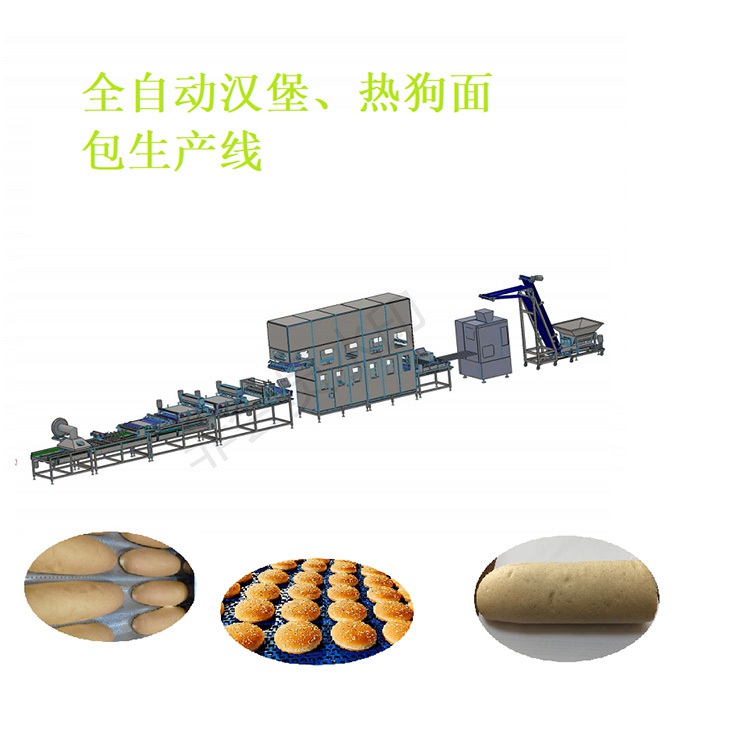

Toast Bread Production Line QLLM-T3

Toast production line is one of our most popular bread production lines, it is customized according to the different needs of customers.

Customers can freely choose one or several kinds of baking equipment to add directly to the original production line or build a completely automated production line. We will provide customers with the highest quality products and services.

The baking equipment is easy to operate. Each single machine or every link has electronic buttons to set parameters. The Chinese and English logos are used to control the smooth progress of production through these control panels.

The toast bread production lines are made of stainless steel or materials that are not easily corroded and have good durability.

Product Description

Being an important consumer product, toast bread is a necessity food in many parts of the world. The production of toast bread requires the dough to go through a series of stages, each open to the potential for mistakes that could disrupt the bread's chemical process, thus the need for automated production. To meet local demand, market players must not only adapt their recipes but also ensure the industrial performance of their line. Therefore, QinLi has designed the toast production line

Tailor-made for large-scale operations, this toast bread production line is designed to maximize output while maintaining uncompromising quality. Ideal for busy bakeries and food processing plants, our production line offers fully automated systems that ensure consistent slicing, toasting, and packaging of your toast bread.

With minimal human intervention required, our Toast Bread Production Line guarantees high efficiency, reduced labor costs, and a consistent end product that meets the exacting standards of the modern consumer. Elevate your toast bread manufacturing process and rely on our cutting-edge solution for reliable, high-volume production.

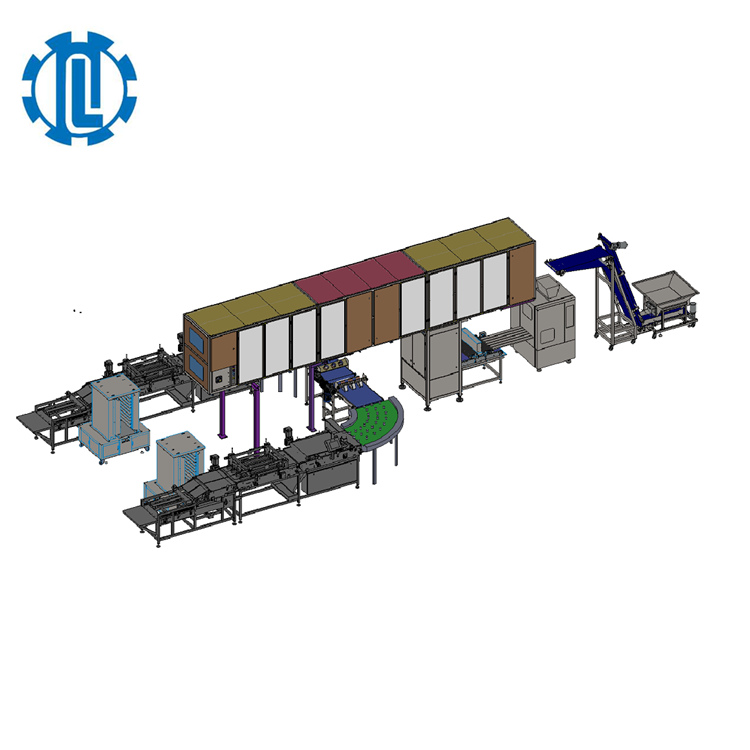

Toast Bread Production Line Details:

Elevate your toast bread production with our sophisticated Toast Bread Production Line. Designed to cater to the unique requirements of commercial bakeries, this high-performance equipment offers a fully automated solution for unparalleled productivity and product consistency. Our meticulously engineered line ensures optimal shaping, baking, and cooling processes, delivering toast bread that meets the highest quality standards every time. Perfect for businesses aiming to increase output without compromising on taste and texture, our Toast Bread Production Line is the ultimate choice for efficient and reliable manufacturing. Request a quote now.

Toast Bread Production Line Parameter:

| Model | Capacity pcs/h | Weight range | Overall size cm | Voltage | Power |

| QLLM-T3 | 1500-2500 | 90-100g | 400*105*220 | 3P-380V50Hz | 27.5KW |

We can provide the best solution according to your factory layout and capacity.

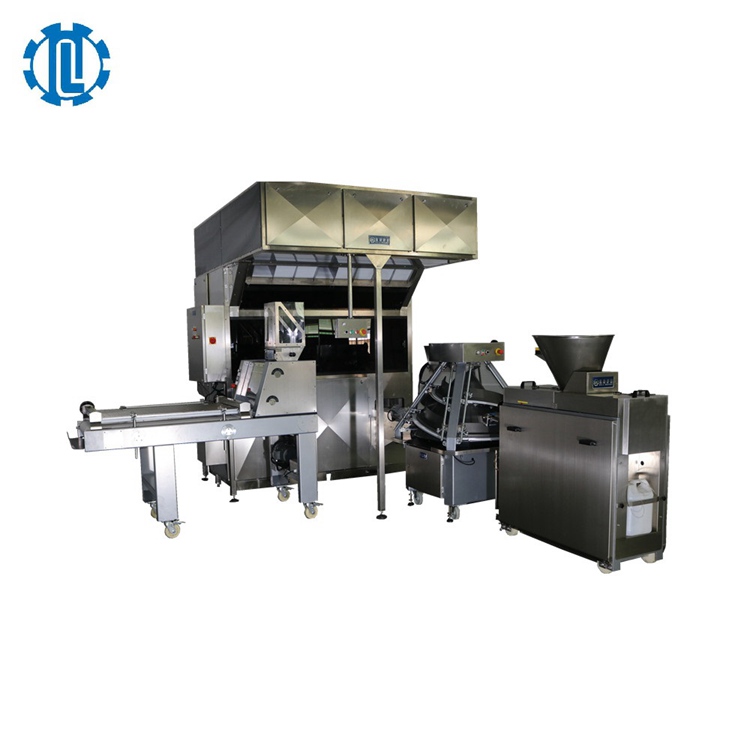

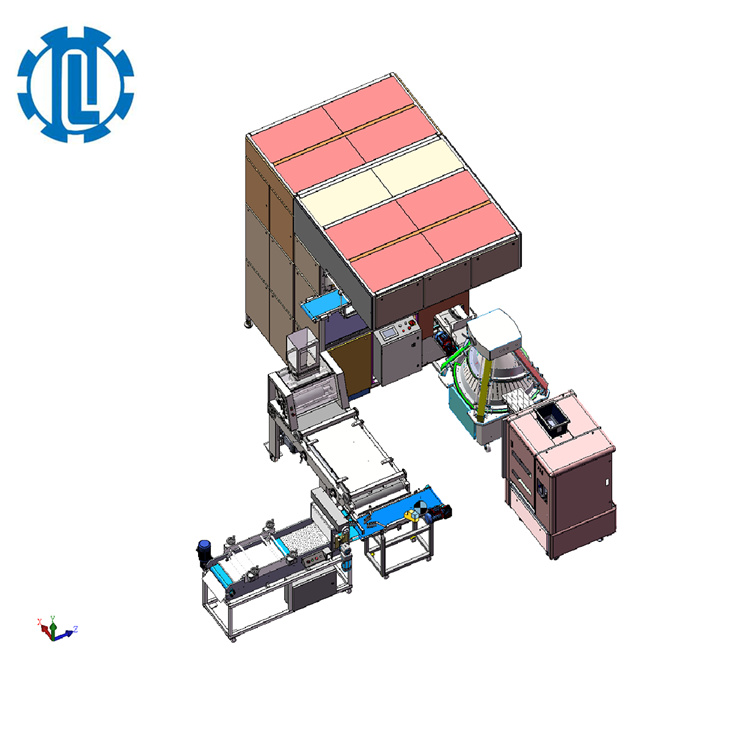

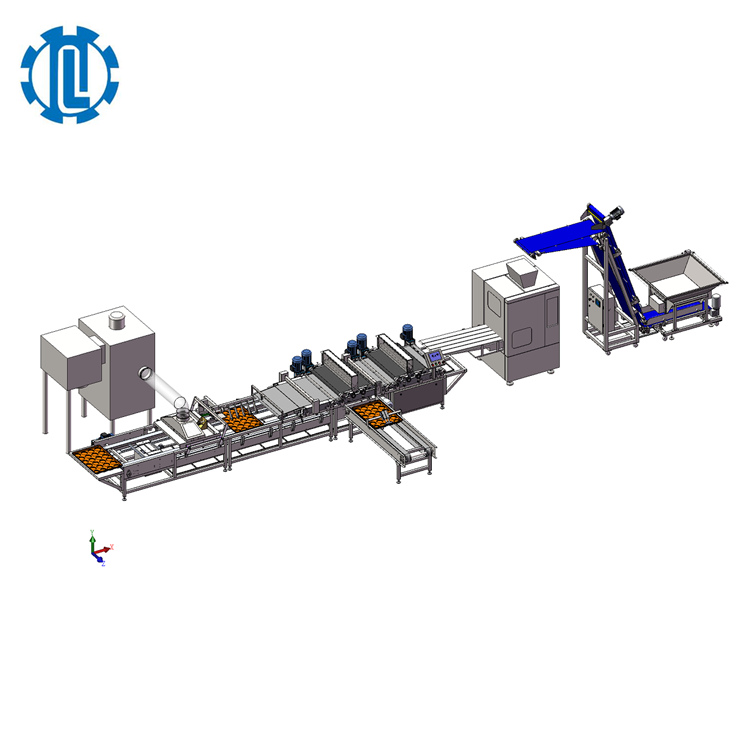

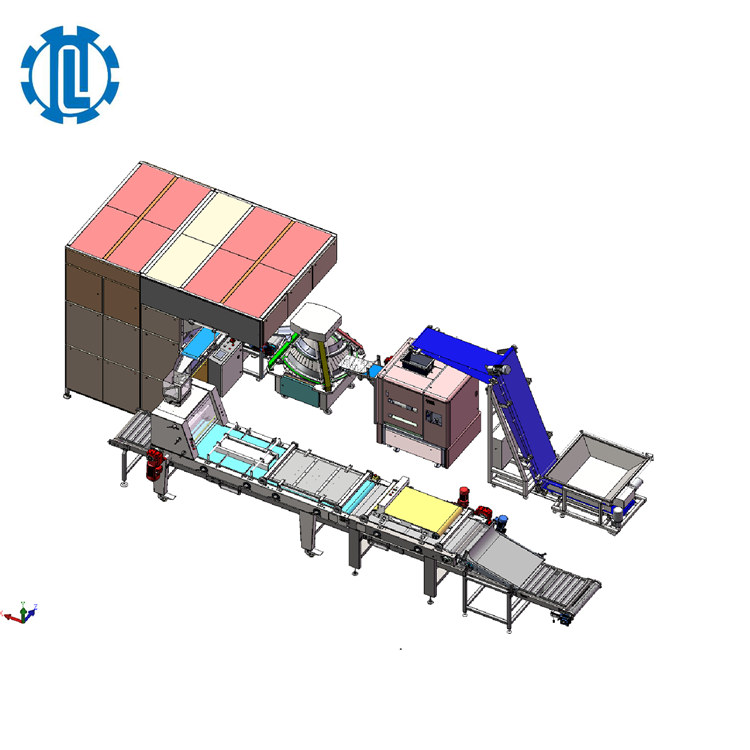

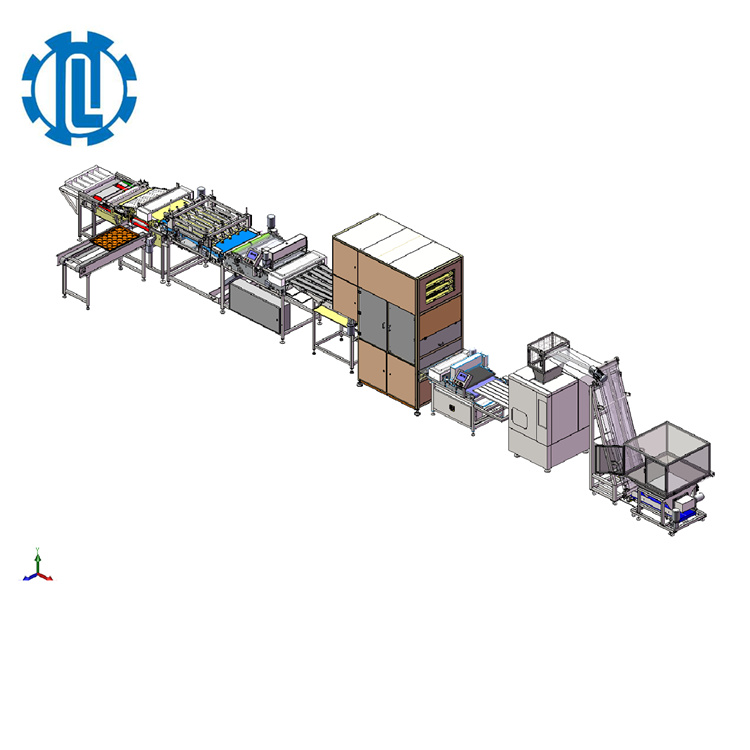

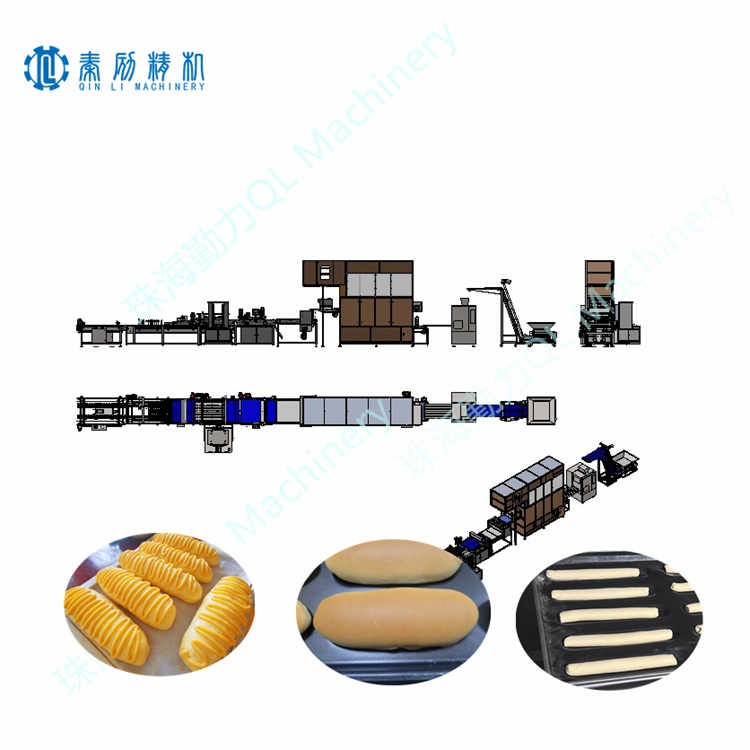

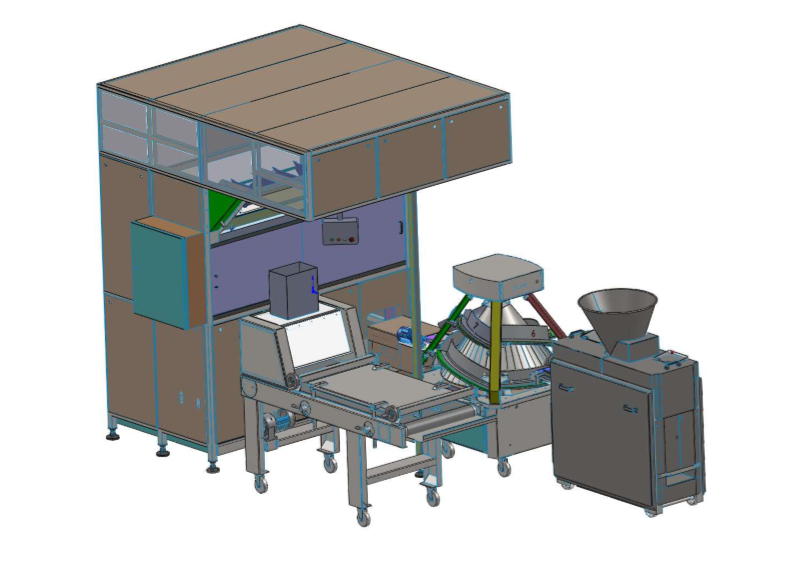

QLLM-T3 Toast Loaf Production Line Composition:

Toast bread production line as follows:

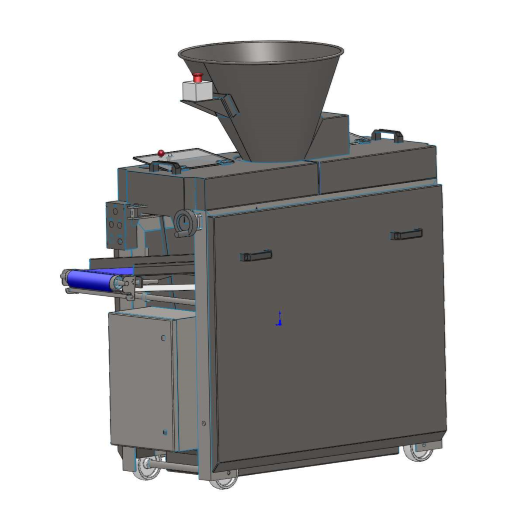

A. Dough mixer

1. Model: QTSD-300

2. Capacity: 1-pocket 750~1500PCS/H; 2-pocket 1500~3000PCS/H.

3. Dough ball weight range: 2-pocket 130~350g; 1-pocket 200~1000g.

4. Capacity of hopper:65KG.

5. Voltage: 3P-5 wire,380V.

6. Power: 1.5KW.

7. Overall size: Length 1600 mm、Width 620 mm、Hight 1550 mm.

B. Doug divider

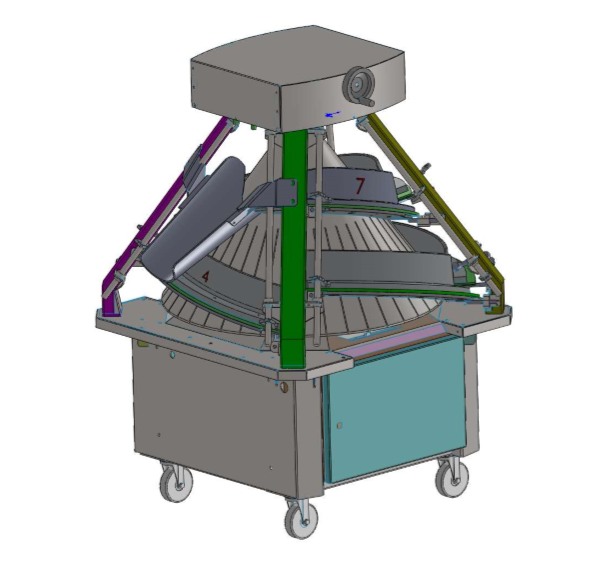

C. Conical rounder

1. Model: QTCR-360

2. Capacity: 4000PCS/H.

3. Rounding weight range: 30~1800g.

4. Length of rounding pathway: 4m.

5. Voltage: 3P-5 wire,380V.

6. Power: 1.5KW.

7. Overall size: Length 1250mm、Width 1050 mm、Height 1520 mm

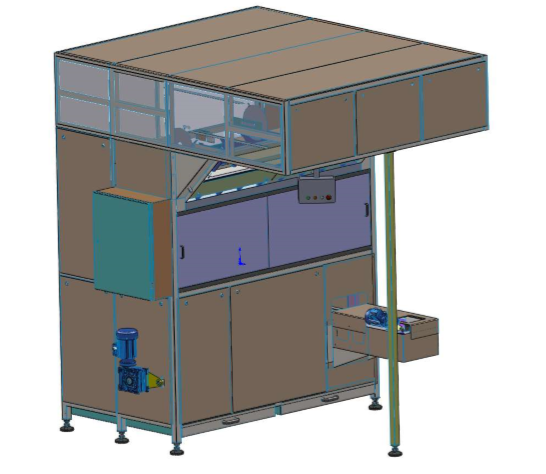

D. Intermediate proofer

1. Model: QTIP- 6/8/10

2. Capacity: 1200/1800/3000 PCS/H

3. Capacity of pocket: 100~1500g.

4. Power: 0.75~3KW

5. Overall size: Length 2510mm, Width 2300mmHight 2850mm

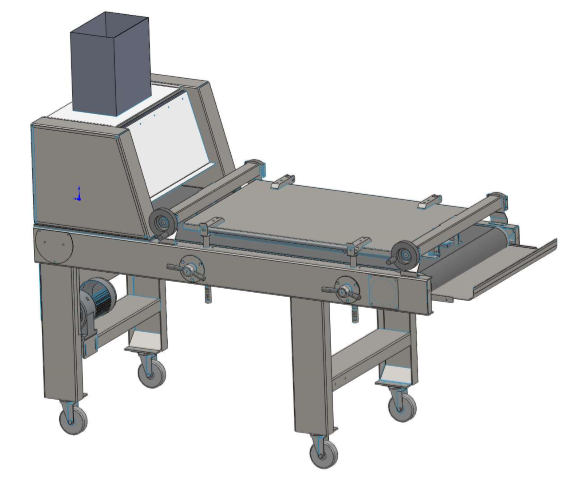

E. Toast moulder

1. Model: QTMO-300

2. Capacity: 3000PCS/H

3. Weight range for molding: 30~1800g

4. Belt width: 650mm

5. Power: 1.1kw

6. Overall size: length 2100mm, Width 900mm, Hight1720mm

QinLi creates custom-made production lines with respective planning & designing to meet the demands of each customer. As per the information from customers about product items, expected production capacity, site actual condition, etc.., we supply the running direction of flowchart and equipment recommendation.

Automatic Toast Bread Line Features:

1. High Efficiency: Automatic toast bread lines are designed to operate with high efficiency, allowing for the rapid production of toast bread in large quantities. The automated processes minimize manual intervention and increase production output.

2. Consistency: These production lines ensure consistent quality and characteristics of the toast bread. The automated processes help maintain uniformity in size, shape, color, and texture of the finished products.

3. Versatility: Automatic toast bread lines are versatile and can handle various types of bread, such as white bread, whole wheat bread, multigrain bread, and specialty bread. The line's settings can be adjusted to accommodate different recipes and customer preferences.

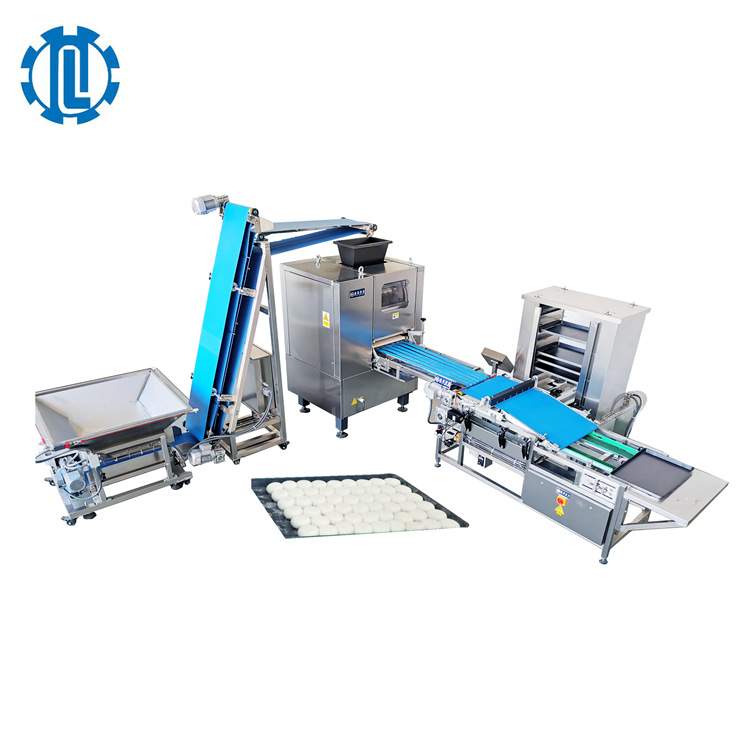

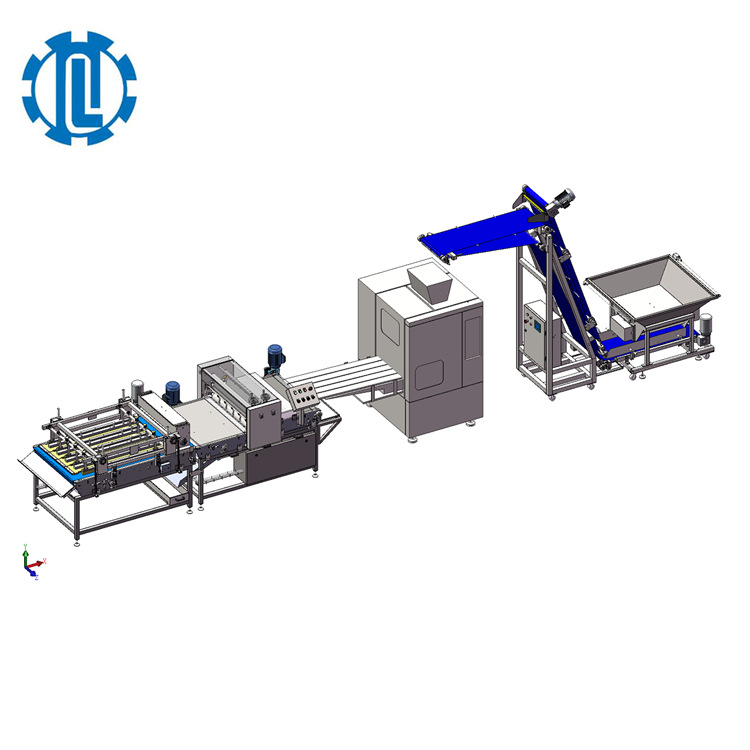

4. Automated Dough Feeding: The production line typically includes automated systems for dough feeding. This involves accurately measuring and delivering the required amount of dough to each stage of the production process.

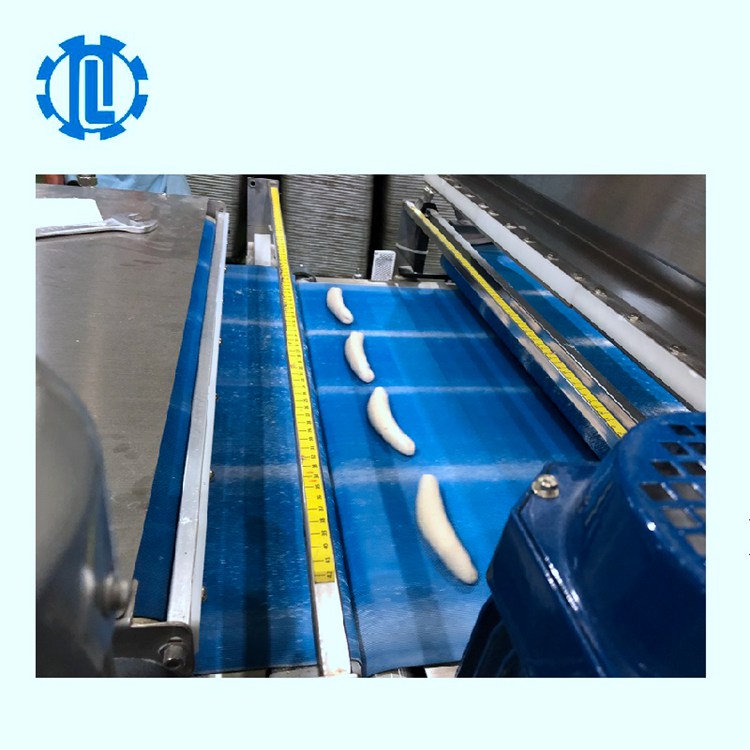

5. Dough Dividing and Shaping: The dough dividing and shaping process is automated, ensuring that each portion of dough is accurately divided and shaped into uniform pieces. This step sets the foundation for consistent toast bread products.

6. Proofing: The proofing process allows the dough to rise before baking. The automatic toast bread line includes controlled proofing conditions to achieve optimal dough expansion and fermentation.

7. Baking: The baking process is automated, with conveyor belts or trays transporting the dough portions through baking chambers. Precise temperature and time controls ensure even baking and a consistent final product.

8. Cooling and Slicing: After baking, the toasted bread is automatically cooled to an appropriate temperature before proceeding to the slicing stage. Automated slicing ensures uniform slice thickness and speed.

9. User-Friendly Controls: The production line is equipped with user-friendly control panels or interfaces that allow operators to monitor and adjust various parameters. This includes setting baking temperatures, proofing times, slicing thickness, and more.

10. Efficiency and Safety: Automatic toast bread lines are designed with efficiency and safety in mind. They incorporate features such as emergency stop buttons, safety interlocks, and sensors to prevent accidents and ensure smooth operations.

Order Our High-Efficiency Toast Production Line Now

Zhuhai QinLi Machinery is a leading manufacturer, supplier and factory of a prestigious Toast Production Line in China. Our Toast Production Line is designed to meet the contemporary need for a fast, efficient and reliable toasting process. With our Toast Production Line, you can toast a wide range of bread products to perfection. The line is designed to handle high-volume output and can be easily customized to meet the specific needs of your bakery or food production facility. Our team of experts has integrated the latest technology and innovative design to ensure that our Toast Production Line delivers consistent toasting quality. The line is user-friendly, easy to operate and maintain, and delivers long-lasting performance. In summary, if you are looking for a trusted and reliable Toast Production Line manufacturer and supplier, then QinLi is the perfect choice. Contact us today to learn more about our Toast Production Line and how it can enhance your production process.