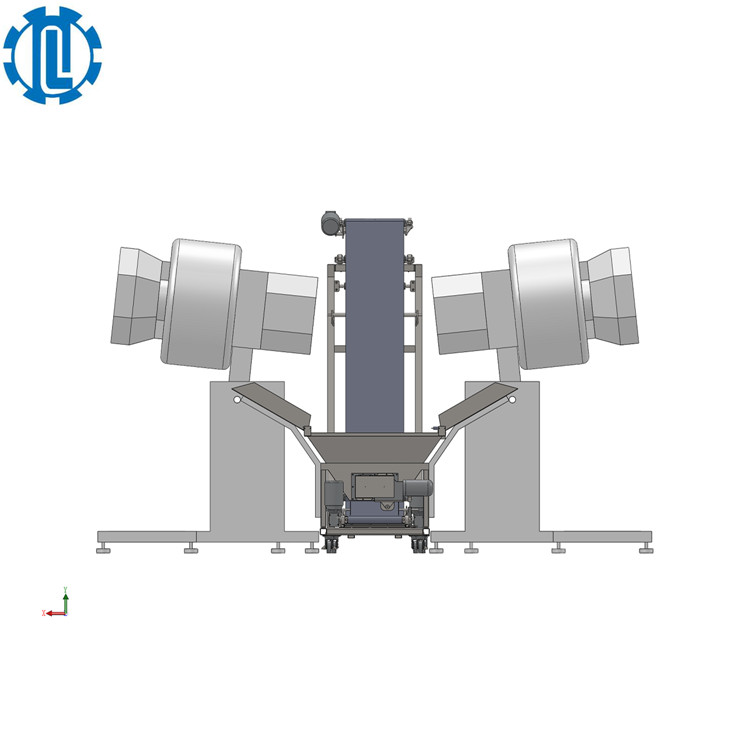

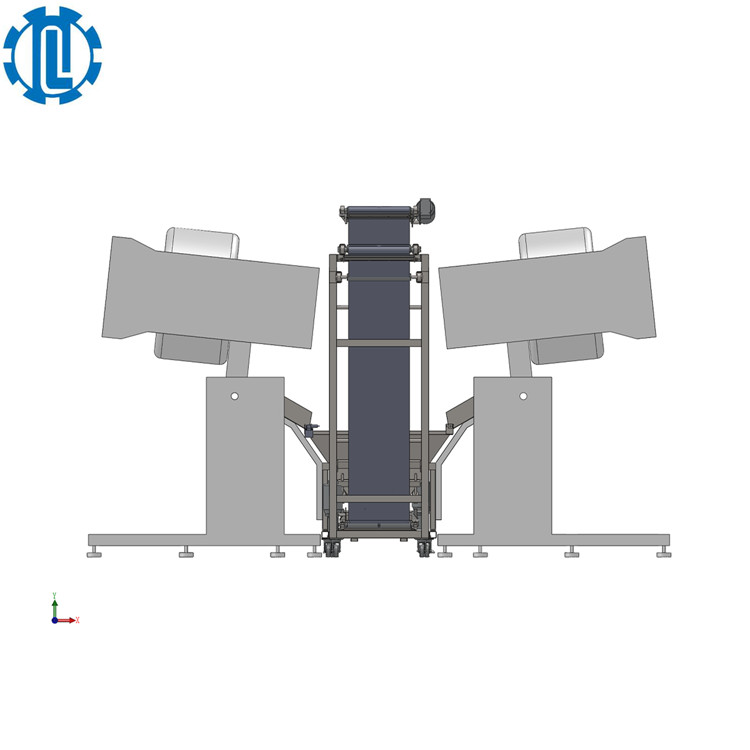

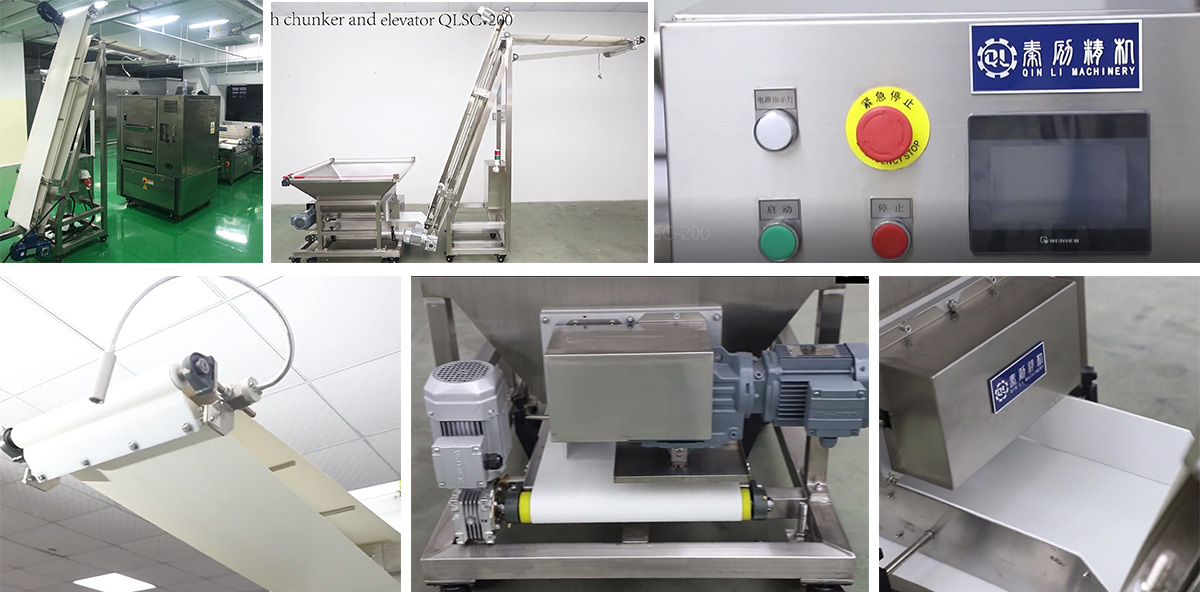

Dough Divider and Lifter QLSC-200

Application:

Divide and feed dough automatically, labor-saving.

Feature:

Triangle knives make it possible to divide dough without gluten damage and keep the original flavor.

Feed the next process automatically, working speed adjustable, without weighting system.

Get one dough piece with one action.

Product Description

A dough divider and lifter is a bakery machine designed to streamline the process of portioning and lifting dough. The dough divider and lifter can transfer the dough bulk portions from the feeding dosing hopper or chunker to the extruder or divider rounder from ground level to a higher level.

Dough Divider and Lifter Details:

A. Fully SUS304 Stainless steel machine casing.

B. Automatic dividing of the dough and feeding to the divider rounder machine.

C. with a sensor, for the dough inspection above the hopper.

D. Conveyor speed 5.5m/min, The Material of the convey belt is food-grade blue PU.

E. Hopper's capacity is 200 kg and equipped with a safety protection device.

F. Equipped with Teflon coated triangle knife for dough dividing, wouldn't damage dough gluten.

| Model | Max Capacity | Overall size mm | Weight range dough piece | Working speed | Voltage | Power |

| QLSC-200 | 4800KG/h | 3470*900*2500 | 6-8Kg | 5.5m/min | 3P-380V50Hz | 1.6KW |

Dough Divider and Lifter Functions:

● Dough Dividing: Accurately divides large batches of dough into uniform portions for consistent baking. Reduces labor time and ensures even sizing, which is crucial for products like bread rolls and pastries.

● Dough Lifting: Transports the divided dough portions from the divider to the next stage of production, such as proofing or shaping. Minimizes handling and preserves the integrity of the dough.

Dough Divider and Lifter Features:

● Adjustable Portion Sizes: Allows bakers to customize the size of dough portions based on specific recipes or product requirements.

● Hygienic Design: Made from food-grade materials that are easy to clean and maintain, ensuring compliance with health standards.

● User-Friendly Controls: Equipped with intuitive controls for easy operation, even for novice bakers.

● Durability: Built to withstand the rigors of a busy bakery environment, ensuring long-lasting performance.

● Space-Saving Design: Often designed to fit within limited workspace areas, optimizing efficiency in the bakery.

Dough Divider and Lifter Benefits:

● Increased Productivity: Automates the dividing and lifting process, allowing bakers to focus on other tasks.

● Consistency: Ensures uniform portion sizes, leading to more consistent final products.

● Reduced Labor Costs: Minimizes the need for manual labor, which can lead to cost savings in larger operations.

Dough Divider and Lifter Applications:

Ideal for bakeries, pizzerias, and food production facilities that require efficient dough handling for a variety of baked goods. If you need more specific information or details about a particular model, feel free to ask!

About Us

Zhuhai Qinli Machinery Co., Ltd is located in Zhuhai City, Guangdong Province, which is a beautiful and economically developed coastal city. As a professional company specializing in manufacturing baking machines and supplying services, we have great advantages of technology background.

Our team is professional in design, manufacture, and sales. Products contain a variety of precision baking Machines, such as Hamburger / Tortilla / Hotdog/pita production line, Dough divider rounder, Moulder, Dough conveyor, Intermediate proofer, Dough extruder, Pita Moulder, seeds sprinkler, and so on.

FAQ:

Q: Are you a trader or manufacturer?

A: Of course, We are a factory with 10 years of professional food machine manufacture, can provide customized machines according to your factory size.

Q: How about the after-service of your product?

A: 1 year warranty. Our engineers were available to service machinery overseas.

Q: How long is your delivery time?

A: The delivery time for a single machine is 15-20 days, and for a production line is 45-60 days.

Q: Why did I choose you?

A: We have been in this line for over 10 years. We can supply a one-stop service with a professional engineers team, exact layout proposal and quality machinery.