How to produce the frozen dough balls and the frozen Dough Store Operation SOP

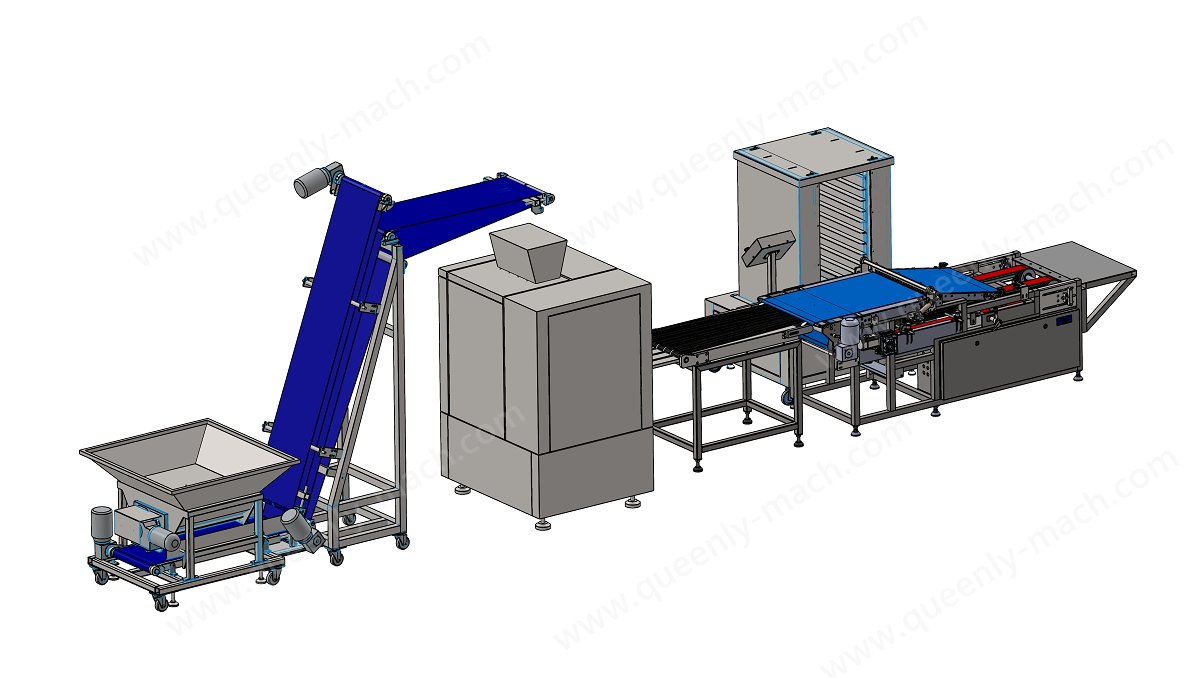

Video of Frozen dough balls forming line as follows:

1. Storage

▲.Keep frozen dough at -18°C or below. Do not refreeze after thawing.

▲.Shelf life: approximately 6 months (refer to package).

▲.Handle gently to prevent gluten structure damage.

2. Thawing

▲.Refrigerated thawing: Transfer dough to 2–5°C storage for 8–12 hours (overnight). Keep covered to avoid surface drying.

▲.Do not thaw at room temperature, as uneven fermentation may occur.

3. Proofing

Temperature: 35–38°C; Humidity: 75–85%; Time: 45–60 minutes.

Dough should double in volume and rebound slowly when gently pressed.

4. Baking

▲.Preheat oven to 170–190°C.

▲. Bake 8–12 minutes for small rolls or 12–15 minutes for burger buns.

▲. Brush egg wash or spray water before baking; demold and cool immediately after baking.

5. Cooling and Storage

▲. Cool on racks for 20–30 minutes after baking.

▲. For temporary storage, keep refrigerated (0–5°C) and use within the same day. Avoid refreezing.

6. Store Usage Tips

Toast burger buns before serving; reheat or fill small rolls as needed.

7. Common Issues and Solutions

▲.Uneven proofing → Extend thawing time and stabilize temperature.

▲.Small volume → Extend proofing duration.

▲.Surface cracking → Increase humidity during proofing.

▲.Wet bottom → Extend cooling time for moisture dissipation.

8. Summary

The key lies in 'slow refrigeration thawing + precise proofing + stable baking.' Following the SOP ensures consistency and quality.

9. Recipe of frozen dough balls

Normal recipe:

| NO. | Raw material | Weight(Gram) |

| 1 | Strong wheat flour | 17000 |

| 2 | Tapioca flour | 3000 |

| 3 | Gluten powder | 600 |

| 4 | Sugar | 1500 |

| 5 | Butter | 1300 |

| 6 | Full egg | 2100 |

| 7 | Ice water | 9000 |

| 8 | Dry yeast | 200 |

| 9 | Salt | 200 |

Total weight | 34900 | |

Mixing process: Low speed 8 Mins,Add butter, High speed 6 Mins. Dough temperature 23-25 ℃ | ||

10. Machines for Dough balls making

▲. Manufacturers for Automatic dough divider rounder

Structural Features: Oil-free volumetric separation, no gluten damage, no need for lubricants, and high production capacity.

Manufacturers:

WP bakery technologies (German)

Koenig Bakery Systems GmbH (Austria)

ZHUHAI QINLI MACHINERY CO.,LTD (China)

Sinmag Group (China) Co., Ltd.

▲.Advantages of Fully Automatic Dough Divider in Frozen Dough Production

★. High Accuracy Ensures Consistent Frozen Dough

Frozen dough consistency after thawing and baking heavily depends on precise initial dividing.

The volumetric distribution system and servo control technology keep dough piece weight deviation within ±1g, ensuring equal weight and density, uniform proofing and baking, improved stability, and reduced defect rate.

★. Gentle Dividing Without Damaging Gluten Structure

Since frozen dough requires secondary fermentation after thawing, maintaining gluten integrity is critical.

The divider adopts low-shear and flexible extrusion principles, preventing gluten tearing, maintaining even gas distribution, and supporting strong recovery and elasticity—ideal for high hydration, high sugar, and high fat formulas.

★. Compatible with High Hydration and Multiple Formulas

Frozen dough usually has a high hydration level (60–70%), and traditional dividing methods tend to stick.

The fully automatic divider uses anti-stick coating or oil-film systems to handle various formulas such as toast, hamburger buns, hotdog buns, pizza bases, and croissants, improving versatility and ROI.

★. Improved Efficiency and Reduced Labor Dependence

Frozen dough production typically requires large-scale, continuous processes.

Dividing speed can reach 6,000–12,000 pcs/hour, seamlessly connecting with automatic rounders, freezing tunnels, and packaging lines—reducing labor costs, shortening cycles, and minimizing human error.

★. Standardization and Data Traceability

Modern dividers can integrate with MES or PLC systems to record batches, track weight data, and automatically adjust dividing parameters.

This ensures compliance with food safety and quality systems such as HACCP and ISO22000.

★. Support for Stable Freezing Processes

Uneven dough sizes cause temperature variation and uneven ice crystal formation during freezing, affecting post-thaw performance.

Accurate dividing ensures uniform freezing rates, preventing overcooling or incomplete freezing, preserving yeast activity and fine crumb structure.

★. Easy Cleaning and Maintenance

Frozen dough contains oil and sugar that can adhere to machine parts.

The divider features modular design and food-grade stainless steel construction for easy disassembly and cleaning, preventing contamination and extending service life

Conclusion

The core advantages of a fully automatic dough divider in frozen dough production are “precise dividing + gentle handling + high efficiency + digital control + strong post-freeze stability.”

It not only enhances consistency and product quality but also supports standardization, cost reduction, and smart factory transformation.

2025-10-13/ 18:37:23

Our Team